Modular Heads

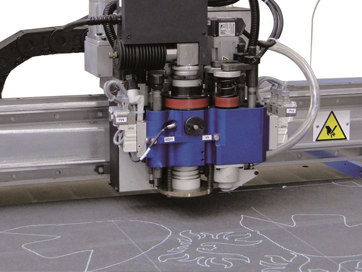

Single Tool Head

The single tool head is a universal module, designed to accept the full range of 40mm tools including pneumatic & electric oscillation, free or driven rotary cutting, kiss cutting, milling-routing, creasing & 45° angle cutting. The versatility of this module makes the cutting system configuration for specific cutting needs very simple & cost-effective. A spanner lock allows for rapid tool changes & the module can work in both pressure & position mode.

Double Tool Head

The double tool head consists of two modules: the first is primarily fitted with the various cutting & milling tools available whilst the second is commonly fitted with the heavy duty creasing tool or the 45° angle knife chuck. The double tool head is commonly used in the packaging industry for companies that cut foam products as well as corrugated materials. .

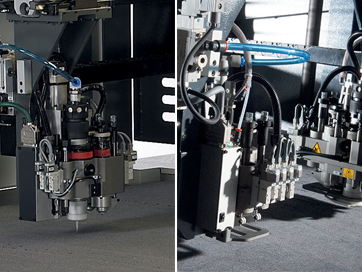

EMHD Head – Milling & Cutting

The EMHD head was engineered & designed to meet the growing demand of the case insert market as well as the processing of various materials used in the petro-chemical & composite industries. The combination of a single tool head and a 3kW electric router spindle, with independent penetration control of both tools, allows for the sequential working of 3-dimensional shapes of any density foams, or very hard materials like plastics, wood, rubber, & composites with extreme accuracy. A liquid cooling system allows the mill to operate 24 hours per day while the working area is kept clean with its own internal dust extraction system.

5-Tool Head

The 5-tool cutting head increases the overall versatility of the ATOM Flashcut and is one of the key factor of its success - the ability to total cut, score cut (partial depth cut) & kiss cut with one module, two auxiliary stations that can be equipped with rotating punches for precise small diameter holes, a creaser wheel or kiss cutting knife, a 4th station that includes a marking pen to apply part #’s and trademarks and a 5th non-rotating punch station that is used on light-weight materials. With this versatile head, the Flashcut now becomes a multi-functional production system for a variety of market sectors.

7-Tool Head

The 7-Tool head offers the same combination as the 5-Tool head yet adds two additional rotating punching-drilling stations for increased flexibility. The pneumatically controlled belt-driven punch stations are primarily used for perforating leather, or for punching small diameter holes in gaskets & textile materials. Four independent punch tools on a single head allows for different hole sizes to be produced on the same job. To accommodate different applications, punches are available in sizes ranging from 0.5mm to 8mm & are made from tungsten carbide or high-speed steel (HSS).

TWINS Modular Head

The standard TWINS series is equipped with a modular head and two independent vertical axes slots which allows for sequential working, matching a wide range of cutting, creasing, marking & punching tools. It is possible to perform different jobs using the most suitable tool for every specific requirement on the same shape. In the same cutting session it is also possible to use the high resolution ink-jet printer & the camera to acquire the fiducial reference points.

TWINS EMH Head

The EMH (Electric Milling Head) allows to sequentially or separately using the cutting knife & the router. It is the ideal solution to combine the process of foam or rigid materials as well a vast number of other materials with a single tool up to a maximum thickness of 50mm. Two different types of routers are available, with a power of 1 or 2.4 kW, air cooling system, variation of the speed rate during the milling & a vacuum cleaning system (dust extraction device) with electric height regulation.