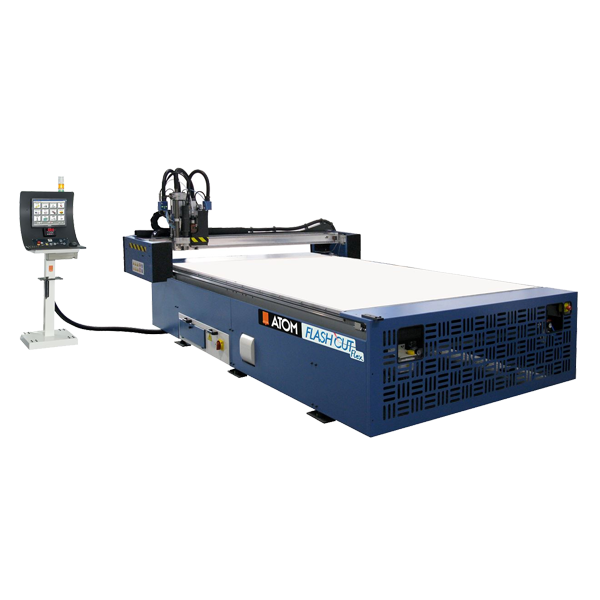

Flashcut Flex

The ATOM Dieless Knife Cutting Systems, Flashcut FLEX Series, is a complete line of oscillating knife cutting tables available in several configurations with either a static or conveyorized (belt feed) cutting surface capable of cutting materials up to 130mm in thickness. The Flashcut is a result of 65+ years’ experience in the cutting field, experience collected by following our customers and paying detailed attention to their feedback and actual cutting needs. The focus of our organization has been to offer our clients accelerated development of new technologies, identifying and solving modern manufacturing problems so that we can improve your current manufacturing process.

ATOM’s automated cutting systems cut with extreme precision and repeatability, to within +/- 0.1mm on most materials. We offer advanced nesting software packages that maximize yields and significantly reduce expensive material waste. Engineered and designed to cut the hardest materials used in the petro-chemical, automotive, aerospace, composites & technical textiles, & packaging industries like compressed non asbestos, 1-2 layer steel inserted graphite, dense rubber, cross linked polyethelene foam, Kevlar, plastics, and many more. Since ATOM develops its technology in close collaboration with its clients, today it is able to offer the most advanced and most applicable cutting solution on the market – the new Flashcut ‘FLEX’.

The new “FLEX” series represents the evolution of the previous architecture of great success with over 1500 units installed worldwide since 2002. The new structure boasts several improvements in technology (cutting head, tooling options, electronics) and software (interface program, CAD compatibility & options) together with the new compact design make them extremely flexible for a wide range of industrial applications. The solid steel rack and pinion system in place of a cogged belt increase the precision and operating speeds of the machine while the two pre-charged linear guide rails and enlarged beam adds to the robustness of the system. The new cutting surface with a higher degree of planarity coupled with the unique partitioned zoned vacuum system add even more suction power improving cut quality and overall accuracy. With the option to add an overhead camera system for material contour recognition, projectors to visualize the cutting layout for assisted parts collection, the modular multi-tool cutting head and the powerful yet simple to use production control software make the Flashcut “FLEX” an efficient, versatile and powerful dieless knife cutting system.

ATOM Flashcut FLEX Series Brochure

ATOM Flashcut FLEX 3026 B3 with Linear Scanner Brochure

ATOM Flashcut Cutting Solutions for Oil & Gasket Brochure